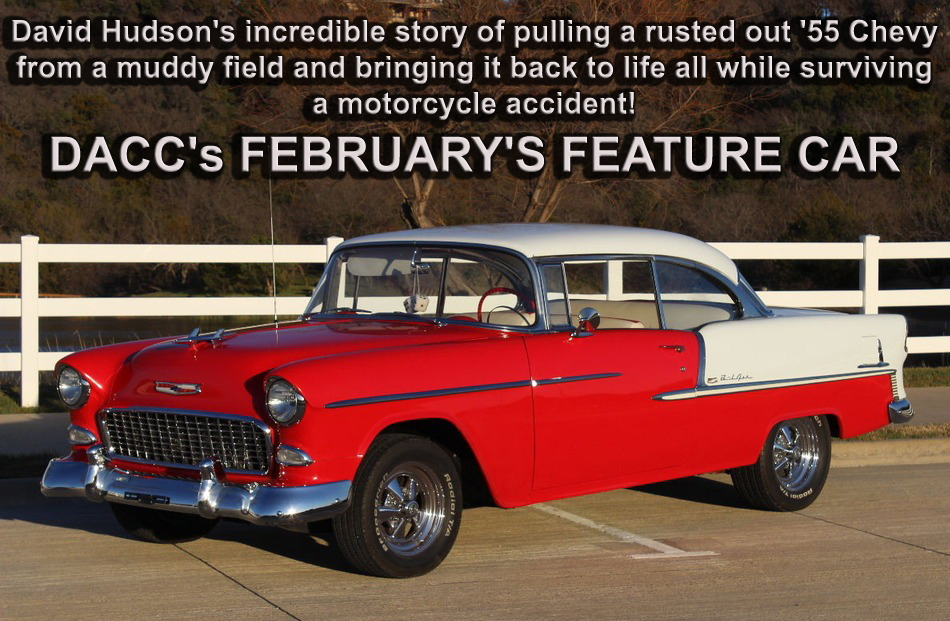

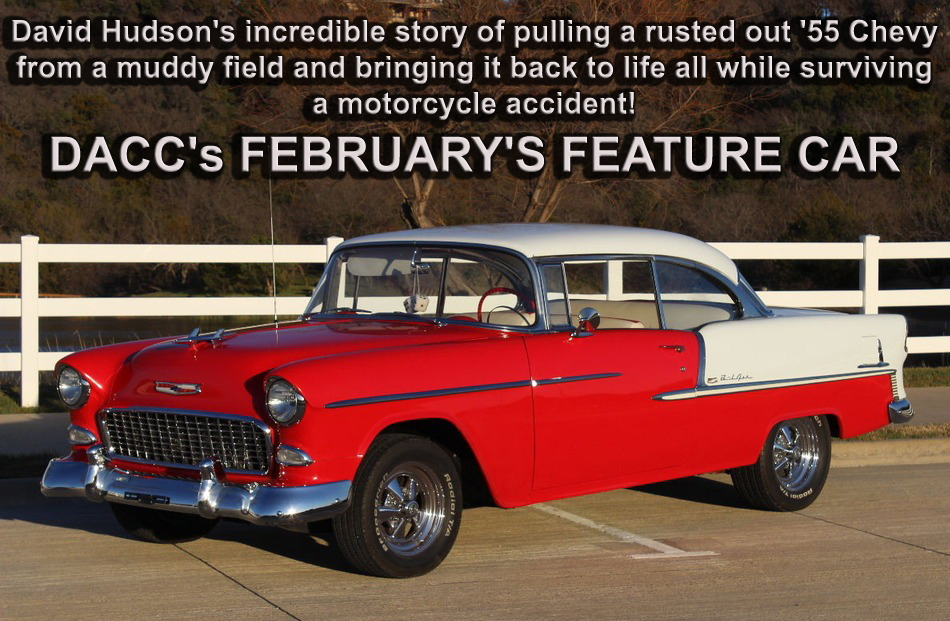

February 2017

Feature Car

I was brought up around cars. My dad drag raced in the

early ‘60s and was a mechanic for many years. I guess he passed down his

mechanical ability to me. We worked on cars together and I became a heavy

equipment mechanic for a number of years. He also instilled in me a passion for

building flying model airplanes. My whole life we built RC model airplanes until

he passed away in 2003. I still model to this day.

In 2010 I got an itch to restore a car and take a break from RC modeling. Tri-5

Chevys to me have always been the trademark car to have. They simply take me

back to the time of early 60s racing, and that whole atmosphere.

I was born in 1957 so I wanted a 1957 Chevy, I started trolling around on

Craigslist and found a guy in Balch Springs that listed a pile of Tri-5s. I

called this gentleman to inquire about a ‘57 Chevy that was listed. He informed

me that the 57’s were sold but he had a ‘55 Chevy two door hard top. I popped

off “I like ‘55s”. So, off I went with my Uncle Jerry in tow to see this ‘55

Chevy. We got there, walked back through a muddy field in the back of his house

and I laid my eyes on it. There it was in all its glory, blocked up on bricks,

missing two tires, and trees growing though it, rusted so badly you could see

all the way through it. Wow, I must say I’m fighting my instinct to run away!,

but I took a gulp and told myself “well I wanted a project car”. As such I

agreed to buy this car.

We came back another day to drag it from the mud (it was a bit drier by then),

the owner was nice enough to give me a couple more rims and have some old nasty

rubber put on them so the car would roll/skid better through the mud.

To release the car from the mud, trees and backyard debris, we had to pull from

a concrete pad about 50 feet away so we tied my suburban with a chain to his

tractor then to the car and proceeded to drag it out. Well that took a while

but ended with success! We then loaded the car onto the trailer and off we

went.

Since my house only has a one car garage, and before this project could begin, I

called my Mom and asked if rebuilding a ‘55 Chevy in her two-car garage would be

ok. She was all over that idea and was already drooling.

So, I put the ‘55 (or what I hope was going to be a car again), in her garage.

She came back home later and decided to take a look in the garage and see this

awesome car I had bought, only to find a rusty, dented, no engine, bald tires,

no seats, broken, rat and snake hotel. She later commented that it did not look

like any ‘55 she remembered. Let’s just say her drooling stopped. She later

confessed to me that she was thinking “what is wrong with my son, what is he

thinking”, my wife pretty much had the same thoughts in her mind about her

husband. I was seeing a finished 1955 Chevy Bel Air two door hard top, the wife

and mom maybe not so much.

We started breaking this thing down to see what parts were needed to rebuild it,

oh man, it needed almost everything. I was doing a frame off restoration but,

the rust was so bad I decided I better leave this body on the frame until enough

metal is replaced to firm it up. So, I leveled the frame out with the body

still mounted and replaced enough metal so the body would support itself on the

rotisserie. During that time, I was buying parts and more parts. I was reading

Chevy forums about the new sheet metal parts not fitting well. I found out that

was true, some parts fit better than others. I really didn’t worry about it,

I’m cutting this car up anyway and I’ll cut the new parts too and make them fit.

Well, its way better than making the whole part yourself.

The floor pan, rocker panels, brackets and associated attaching parts were

mainly rust flakes attached together by gaping holes. I did not know where to

start on the inside, so I decided to start my work by restoring the outside and

working inward. The outside skins and gaps were fixed, if there was a variance

in the sheet metal it would push the differences to the inside where it would

not be seen. I mainly confined my work to weekends and time off from my day

job.

The day came when enough sheet metal had been replaced and I called to schedule

the “DACC WRENCHES” to help pull the body off the frame (THANK YOU GUYS!). I

was then able to finish out the bottom pan area with it off the frame. I then

restored the frame and made a rolling chassis with power disk brakes, CPP 500

steering box, adjustable rear drums, alternator, and a place for AC (not in

yet). The 327 engine (rebuilt by Marvin Cowden) was installed in the rolling

chassis along with a Muncie 4 speed. Once I finished the bottom of the body and

painted the firewall, we lowered the body back onto the frame and bolted it in

place. I’m was thinking at this point I might actually be able to get this ‘55

back on the road again.

Body prep for painting is a bear, many long hours were spent blocking, priming,

blocking, priming, painting, color sanding, and well you get the picture.

The time finally arrived when the car was painted, buffed and ready for the

decorations, such as windows, stainless, dash, and all those things that scream

1955 Chevy. I can’t describe how I felt at this stage of the restoration.

Every knob, stainless strip, light that lit up was like an adrenalin shot. I

needed this after all the years of labor.

I have been driving the car for a while now, but it’s not yet totally finished

(I’m very close), after 5-1/2 years of labor and dreams, I simply can’t resist

driving it. Early on when I started driving the car, it was breaking down

often, so much so that nobody wanted to ride with me.

I would pull over and fix what I could, other times calling my lovely wife to

come rescue me and the ‘55 from the side of the road. Well, I have worked all

the kinks out and now my wife gladly climbs into the passenger seat. Oh and by

the way, my mother’s high point of the day is when we go cruising. It’s like

her dream came true, she is 18 all over again.

An interesting fact during the restoration. I was in a motorcycle accident that

caused a 9 month pause in the work, was hurt pretty bad. My pelvis was broken

in three places. The doctor temporally installed titanium screws and rods onto

my pelvis to hold it together. Time came to remove the rigging (7 months) and I

asked to have all the rods and pieces. Well let’s say I have a really cool

titanium throttle linkage on the carb of my car now!

David & Joann Hudson

Grand Prairie, Texas

MORE PHOTOS

HERE